Subsea Insulation

Subsea Insulation Services

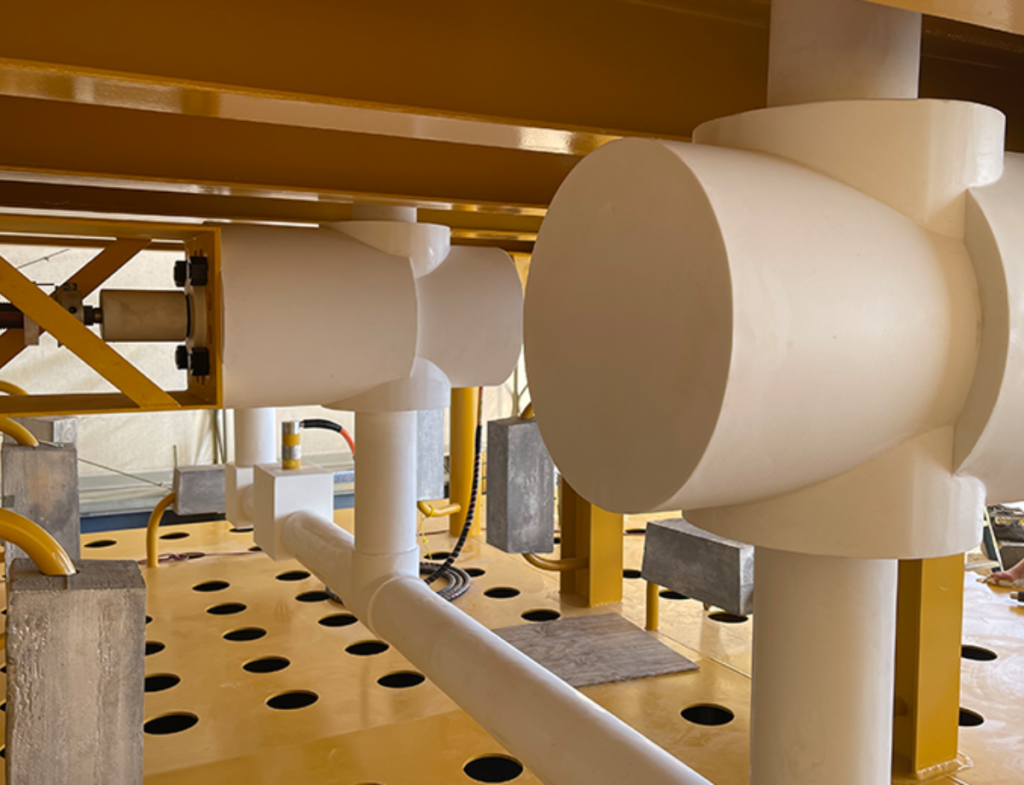

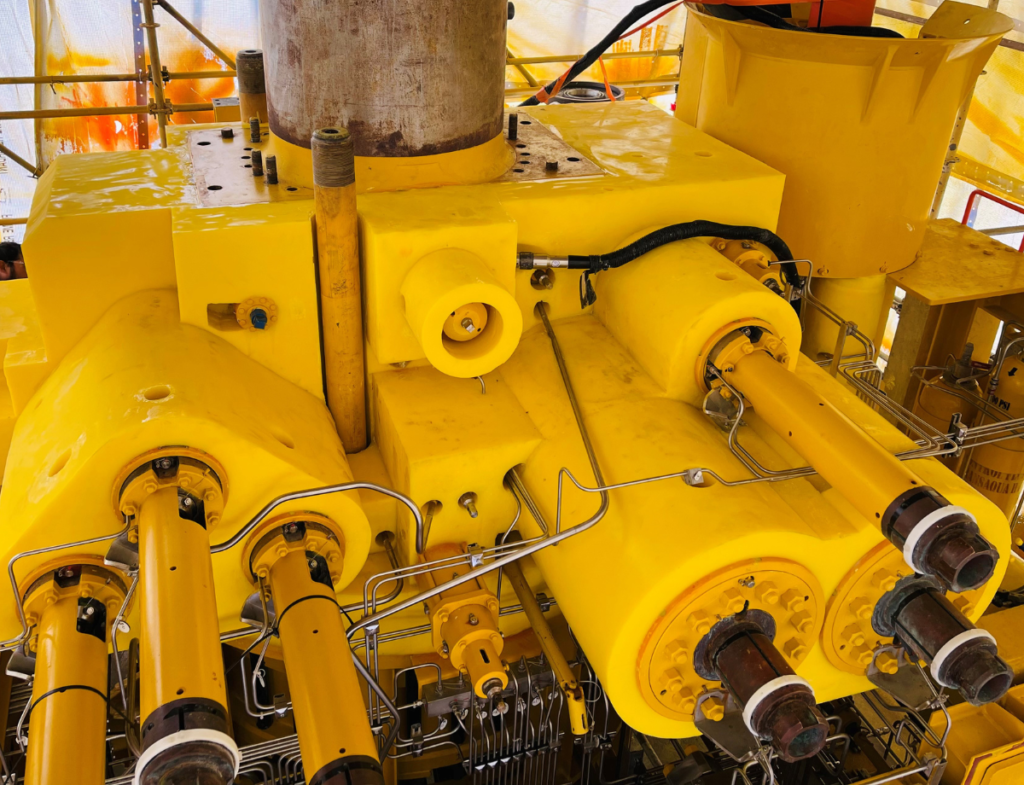

SAS is an approved global applicator specializing in subsea thermal insulation application on a broad range of complex geometry wellhead equipment to meet specific project requirements, including Trees, Manifolds, Jumpers, PLETs, Connectors, and Shrouds.

Insulation Materials:

- Solid and Syntactic Silicone

- Dow/XTI-1003

- TechnipFMC/Novolastic XL

- TechnipFMC/Novolastic XG

- Epoxy/Urethane Hybrid

- Rosehill Offshore/Flexilon RS-3060

- Rosehill Offshore/Flexilon RS-3604

- Solid Polyurethane

- Dow/Various

- BASF Elastoshore

- Hydrocarbon

- ODYSEA GLDX

Subsea Corrosion Coatings:

- Full spray applied coatings and stencils on assembled trees

- Conventional epoxies and marking

- High Build Epoxy Field Joint Coatings

- Canusa HBE-95

- Denso Protal 7200

- SPC SP2888

Subsea Flow Assurance

Every project delivers Safety, Quality & Performance

Complexity

Our cast in place insulation systems can be readily applied to complex geometry utilizing in-house designed moulds that are either pre-fabricated or built at the work location, depending on equipment complexity.

Application Time

SAS provides thermal management solutions with industry leading application times, lowering risk on project deadlines. Included is a system that allows for jumper metrology weld insulation to be completed in 24 hours.

Portablility

The insulation application equipment we employ is portable and can be mobilized worldwide, and provides consistent ratios, thorough mixing, and volume outputs to meet tight schedules.

Our Experience Speaks for Itself

Connect With Us and Get Started

We have two office locations ready to serve you – our main office and Blastyard in Baton Rouge, LA and our secondary office in Houston, TX. Contact us today to discuss your needs.

LOUISIANA

1331 Hwy 190 W

Port Allen, LA 70767

225-383-0700

HOUSTON

19140 Northpine Drive

Spring, Texas 77388

281-350-3600